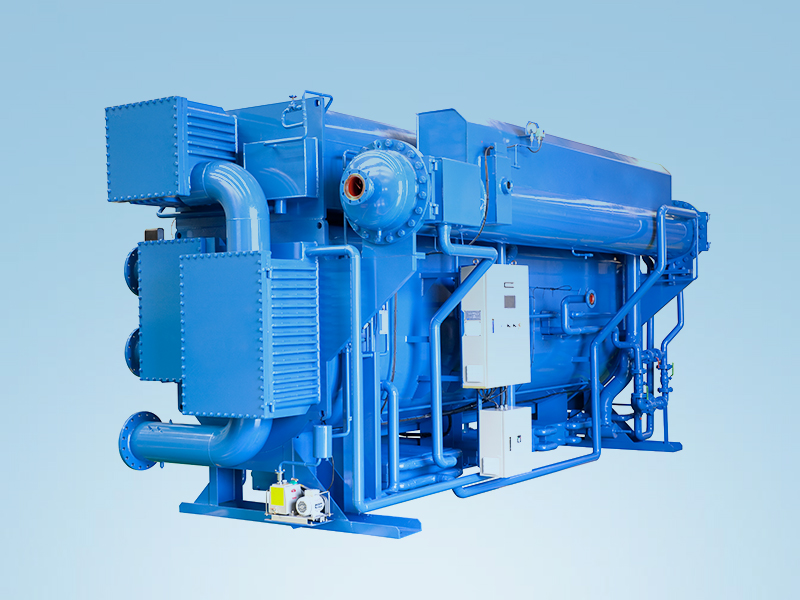

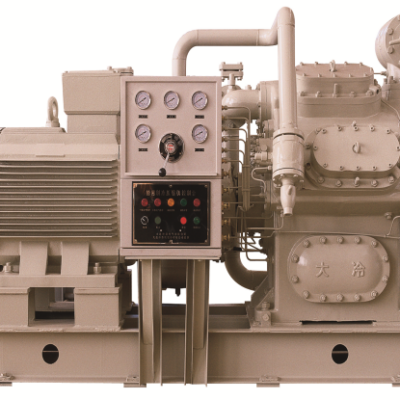

Double Effect Steam Driven Absorption Chiller

Call for Price

Achieve high efficiency and energy conservation through applying inverters

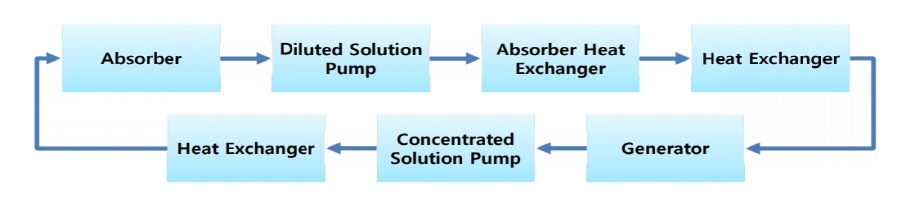

We controlled the solution circulation rate optimally through controlling absorption liquid pump inverters to greatly improve the partial load efficiency enabling energy-saving operation. We also greatly reduced the time to reach the rated cooling capacity through controlling the absorption liquid circulation rate optimally.

· We use evaporators and high-performance special absorber tubes and can achieve high efficiency through the best tube arrangement (high-efficiency chillers) · high-performance solution heat exchangers (high-efficiency chillers) · minimize the installation area, and greatly reduce operational costs

Improve durability through structure design

to prevent the bursting of heat tubes

In order to prevent the bursting of heat tubes because of heat tube resonance occurring while rapidly exchanging heat in high-temperature generators, we increased the durability of chillers through scientifically designing them to stop the resonance of heat tubes.

High-efficiency drain heat retrieving system

We installed steam traps and drain heat exchangers to promote elimination of just condensed water (but not steam) through drain outlets of high-temperature generators. In this way, the temperature of condensed water drains drops to lower than 95℃, maximizing the efficiency of chillers through raising drain heat recovery.

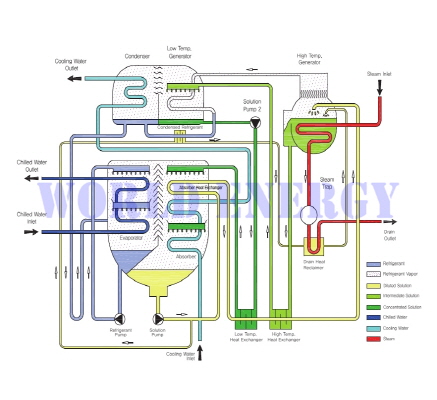

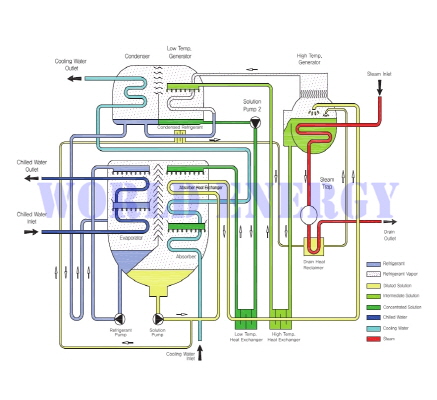

Construction of a high-efficiency steam-type double effects absorption chiller cycle

The body of a chiller is constructed by an evaporator, the lower part of an absorber, a condenser, upper part of a low-temperature generator, a high-temperature generator, a high-temperature heat exchanger, a low-temperature heat exchanger, solution (dilute and concentrated solution), a refrigerant pump, a steam trap and a heat retriever.

The body of a chiller is constructed by an evaporator, the lower part of an absorber, a condenser, upper part of a low-temperature generator, a high-temperature generator, a high-temperature heat exchanger, a low-temperature heat exchanger, solution (dilute and concentrated solution), a refrigerant pump, a steam trap and a heat retriever.

Reviews

There are no reviews yet.